The Power of Inflatable Plugs in Industrial Applications

Introduction

In the ever-evolving landscape of industrial applications, businesses are constantly seeking innovative solutions to enhance efficiency and safety. One such solution that has gained significant popularity is the use of inflatable plugs. This article will explore the remarkable features and advantages of inflatable plugs, specifically focusing on their ability to improve processes and ensure workplace safety across a range of industries.

Enhancing Efficiency

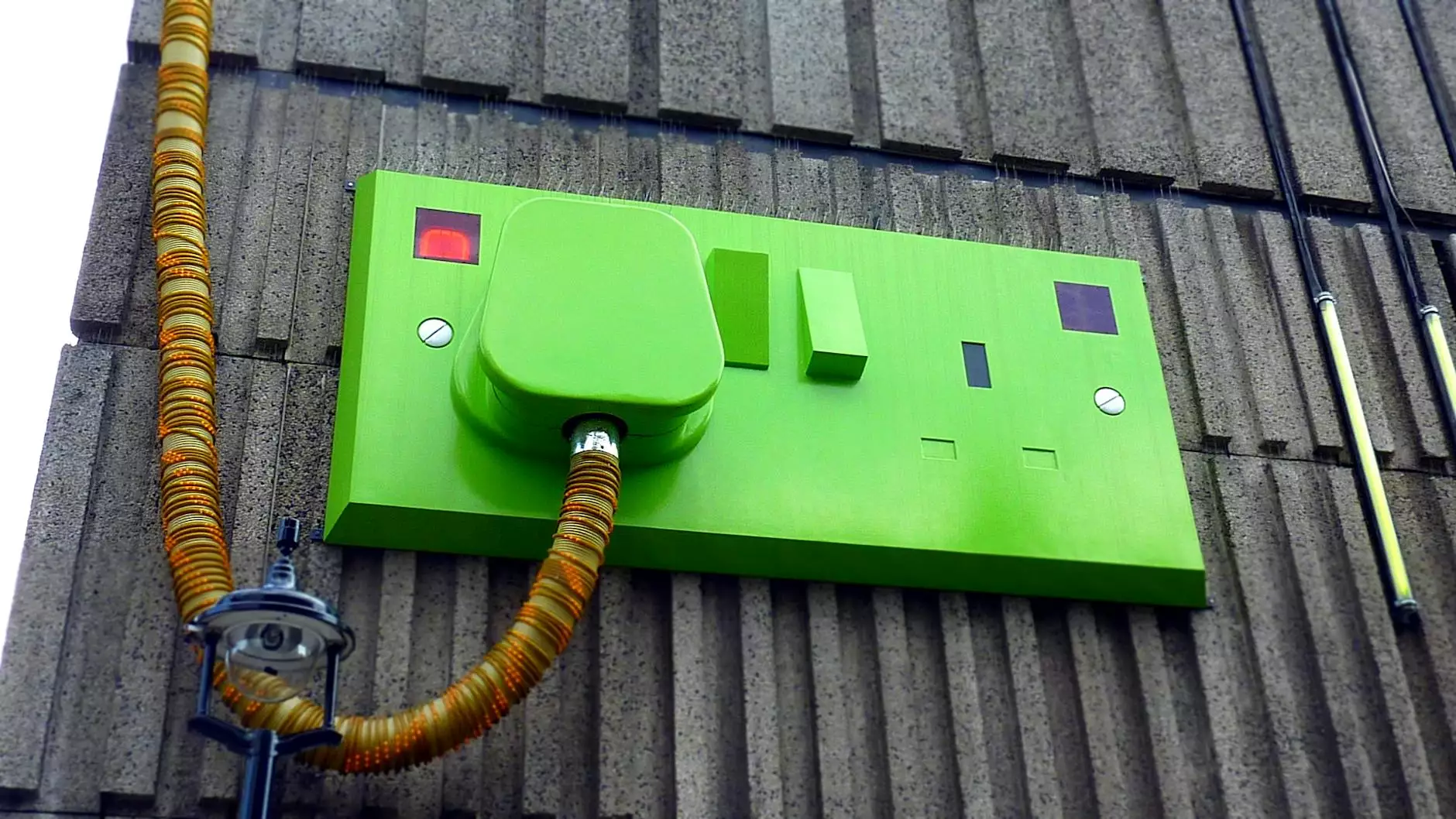

Inflatable plugs, also known as pneumatic plugs, are versatile devices used to seal, block, or isolate sections of pipes, ducts, or other hollow structures. They are typically made of durable materials such as reinforced rubber or fabric-coated nylon and can be easily inflated to create a tight seal. The ability to quickly insert and inflate these plugs significantly reduces downtime during maintenance, repairs, or testing.

Increased Productivity

By employing inflatable plugs, businesses can minimize disruptions to their operations, allowing for faster turnaround times in critical activities like pipe repairs or equipment maintenance. The efficiency gained from using inflatable plugs translates into increased productivity and cost savings, as valuable resources can be utilized more effectively.

Easy Installation and Removal

Unlike traditional sealing methods, such as welding or bolted flanges, which require time-consuming installation and removal processes, inflatable plugs offer a simpler and quicker solution. The user-friendly design allows for easy insertion, inflation, and deflation, streamlining procedures and reducing labor requirements. This level of simplicity and convenience makes inflatable plugs an attractive choice for businesses seeking efficient solutions.

Ensuring Workplace Safety

Workplace safety is paramount in any industrial setting, and the use of inflatable plugs contributes significantly to creating a safer work environment. These plugs offer various safety benefits, which are particularly crucial in industries that deal with hazardous materials, high-pressure systems, or critical infrastructure.

Preventing Accidents and Hazards

Inflatable plugs act as reliable barriers, preventing the release of hazardous substances or the ingress of unwanted materials during maintenance or repair work. By effectively isolating sections of a pipeline or duct, inflatable plugs minimize the risk of accidents, leaks, or contamination that could harm workers or the environment.

Pressure Testing and Maintenance

When conducting pressure tests or maintenance procedures on pipelines or other systems, inflatable plugs provide a secure and controlled environment. By isolating specific sections, businesses can ensure accurate pressure readings, detect potential weaknesses, and proactively address maintenance needs. Inflatable plugs become indispensable tools in maintaining system integrity while prioritizing the safety of workers.

Inflatable Plugs in Various Industries

The versatility of inflatable plugs allows for their effective use across a wide range of industries. These essential tools have found applications in the oil and gas sector, chemical processing plants, manufacturing facilities, and wastewater treatment plants, among many others.

Oil and Gas Industry

In the oil and gas industry, inflatable plugs play a crucial role in pipeline maintenance, repair, and testing. They enable the safe execution of tasks such as hot tapping, hydrostatic testing, and pipeline isolation, ensuring efficient operations and reducing the risk of accidents or environmental damage.

Chemical Processing Plants

Chemical processing plants often handle hazardous substances, making safety a top priority. Inflatable plugs offer a reliable solution for isolating sections of pipes, tanks, or vessels during maintenance, cleaning, or repairs. They enable workers to handle potentially dangerous materials without compromising safety or productivity.

Manufacturing Facilities

In manufacturing facilities, inflatable plugs find applications in various processes, including leak testing, quality assurance, and equipment maintenance. These versatile tools allow for efficient workflow management and mitigate the risks associated with product contamination or equipment failures.

Wastewater Treatment Plants

In wastewater treatment plants, where pipelines and drainage systems require regular inspection and maintenance, inflatable plugs ensure the safety and integrity of the infrastructure. By using inflatable plugs, these facilities can efficiently isolate sections of the system for repairs, cleaning, or upgrades while minimizing the risk of wastewater leaks or environmental hazards.

Conclusion

The utilization of inflatable plugs significantly enhances efficiency and improves workplace safety across numerous industries. These versatile devices offer quick and reliable sealing, blocking, and isolation solutions, reducing downtime, and increasing productivity. Moreover, inflatable plugs contribute to a safer work environment by preventing accidents, containing hazardous materials, and ensuring controlled pressure testing and maintenance procedures.

For businesses operating in industries where the efficiency of operations and worker safety are of utmost importance, integrating inflatable plugs into their processes provides long-term benefits. As the demand for innovative solutions grows, the power of inflatable plugs will continue to play an integral role in shaping the future of industrial applications.